Virgin Aluminium vs. Recycled Aluminium

Aluminium is a popular material in modern interiors – from kitchen cabinets to wall panels and doors. It’s light, strong, and lasts long, which makes it a great choice. However, many people don’t realize how much energy is used to make it, especially depending on how it’s produced – either from raw materials or from recycled scrap.

This article explains the difference in energy use between making virgin aluminium and recycled aluminium, and why recycling is the better choice for the environment.

What is Virgin Aluminium?

Virgin aluminium is made from a natural mineral called bauxite. The process to turn bauxite into aluminium involves two main steps:

- Bayer Process – Bauxite is refined into alumina (a white powder made of aluminium oxide) using heat and chemicals.

- Hall-Héroult Process – Alumina is melted and electricity is used to break it down into pure aluminium metal.

This step uses a lot of electricity.

Making virgin aluminium takes a huge amount of energy, especially in the second step. In fact, it’s one of the most energy-hungry industrial processes in the world.

What is Recycled Aluminium?

Recycled aluminium is made from used aluminium items, like cans, old frames, or panels. These are collected, sorted, and melted down to be used again.

Here’s how recycling aluminium works:

- Collection and Sorting – Used aluminium is gathered and separated into different types.

- Melting – The scrap is melted in a furnace. This step uses much less energy than making virgin aluminium because it skips the heavy chemical and electrolysis steps.

- Casting – The melted aluminium is then shaped into new products.

Why Recycling is Better

Recycling aluminium uses up to 95% less energy than making it from raw bauxite. It also reduces waste and pollution. So, whenever possible, choosing recycled aluminium is the smarter and greener option.

Environmental Impact: Carbon Emissions

The energy used in aluminium production affects how much CO2 (carbon dioxide) is released:

- Virgin aluminium: Producing 1 tonne creates 8 to 12 tonnes of CO2.

- Recycled aluminium: Creates up to 95% less CO2.

This big drop is because recycling uses less energy and avoids mining and processing raw materials.

Saving Money and Resources

Recycling aluminium is not just good for the planet — it’s cheaper too. It saves:

- Natural resources like bauxite and water

- Energy

- Money for manufacturers

That’s why more industries prefer recycled aluminium — it cuts costs and helps them go green.

Looking Ahead: A Greener Future

As more people learn about the environmental costs of virgin aluminium, demand for recycled aluminium is rising. Recycling technologies are also improving, making the process even faster, cleaner, and cheaper.

Future efforts focus on:

- Recycling more aluminium products

- Better collection and sorting of scrap

- Using newer, low-energy recycling technologies

With these steps, recycled aluminium is becoming the smarter, more sustainable choice.

Recycled aluminium is clearly the better option for Maars as well, when it comes to saving energy and protecting the environment. It uses much less energy, creates fewer carbon emissions, and reduces the need for raw materials like bauxite.

By choosing recycled aluminium, we can save natural resources, cut pollution, and fight climate change. As recycling technology keeps improving, the benefits of using recycled aluminium will only grow.

While virgin aluminium is still needed in some cases, using more recycled aluminium is a key step toward a greener, more energy-efficient future.

Reduce Reuse Recycle

At Maars, we are committed to moving towards a circular economy, where materials are continuously reused, not wasted. As part of this commitment, we’re placing greater focus on the use of recycled aluminium in our products.

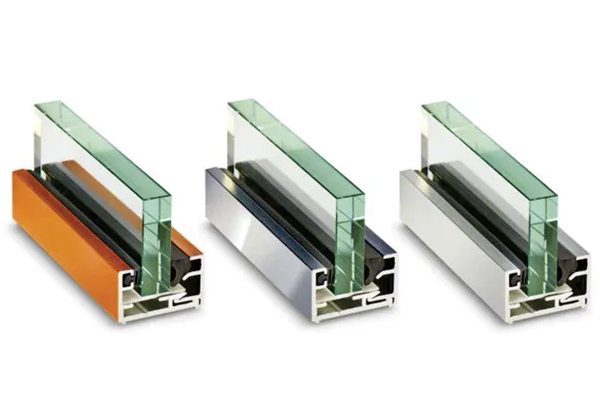

Aluminium is a material that can be recycled repeatedly without losing its quality, and we see this as a major opportunity to reduce our environmental impact. That’s why we are not only incorporating more recycled aluminium into our profiles, but also developing processes to regenerate and repurpose these profiles at the end of their life cycle.

Instead of ending up in landfills, old maars profiles can be collected, recycled, and reintroduced into the production cycle — helping us close the loop. This shift not only reduces waste and conserves natural resources, but also supports a more sustainable and responsible way of manufacturing.

At Maars, we believe that every step toward a circular system is a step toward a cleaner, more sustainable future.